- Home

-

Products

Comminution EquipmentScreening EquipmentGravity Separation EquipmentMagnetic & Flotation Equipment

-

Solutions

Gravity Separation for Hard Rock

- Rock Gold Ore Gravity Separation Solutions

- Primary Tin Ore Gravity Separation Solutions

- Chromite Ore Beneficiation Solution (Gravity + Magnetic Separation)

- Solution for ilmenite ore dressing (gravity + magnetic separation)

- Zirconium Ore Beneficiation Solution (Gravity + Magnetic + Electrostatic Separation)

- wolframite beneficiation solutions

- Barite Gravity Separation Solutions

- Antimony Ore Beneficiation Solutions (Gravity + Flotation)

- Waste incinerator bottom ash sorting solutions

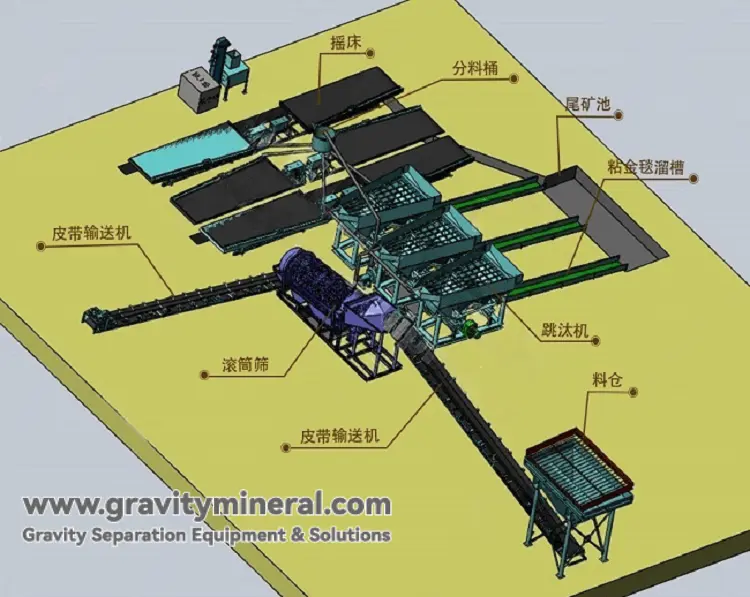

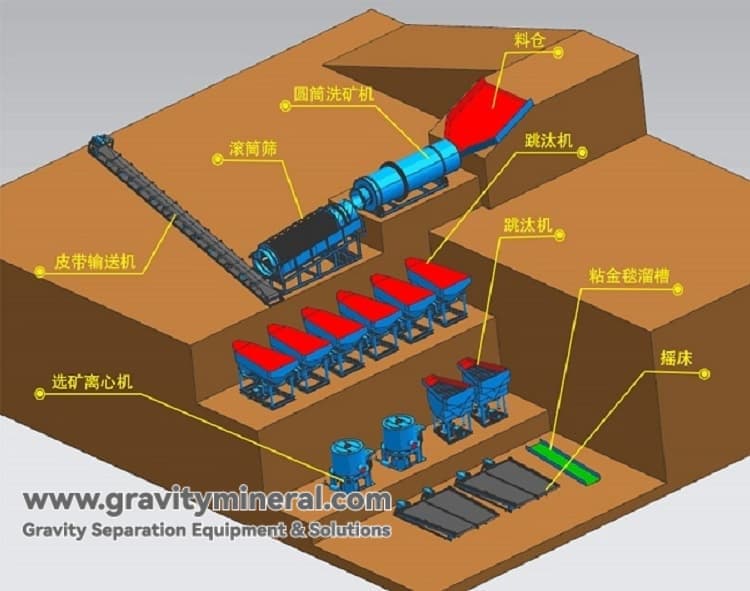

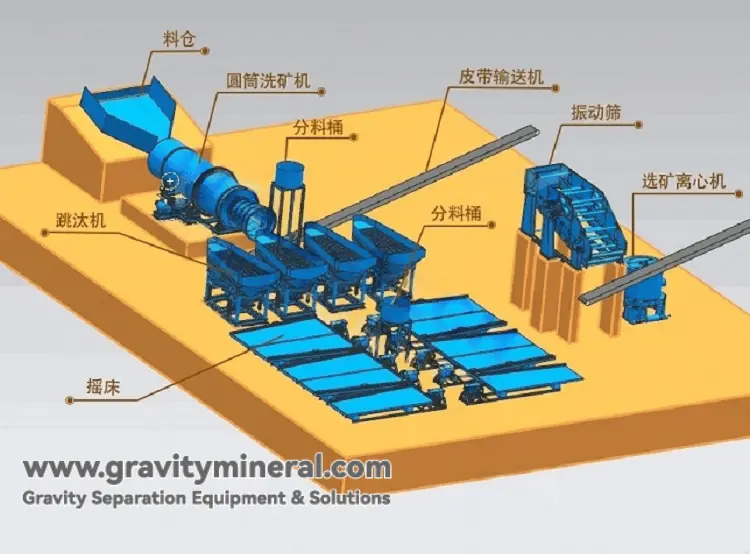

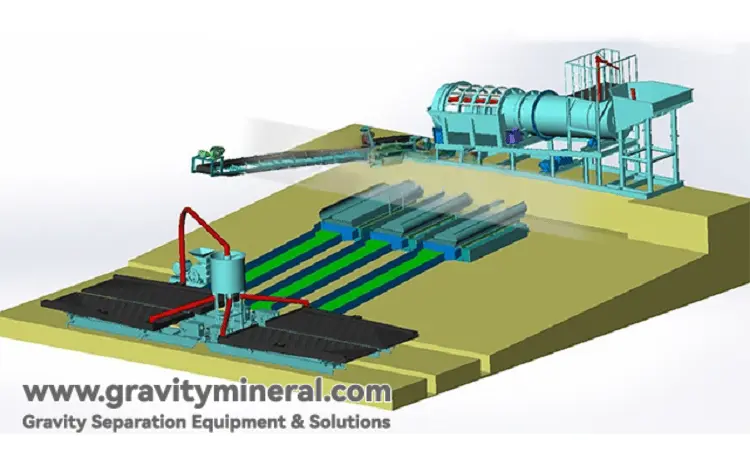

Gravity Separation for Placer Deposits- Alluvial Gold Ore Gravity Separation Solutions

- Tin Alluvial Ore Gravity Separation Solutions

- Coastal Placer Ore Beneficiation Solution

- Integrated Beneficiation Solution for Titanium-Zirconium Placer Ore (Gravity-Magnetic-Electrostatic)

- Chrome Alluvial Ore Beneficiation Solution (Gravity + Magnetic Separation)

- Offshore Tin Placer Ore Gravity Beneficiation Solution

- Gemstone Sand Ore Gravity Separation Solutions

- Zircon Sand Beneficiation Solution (Gravity + Magnetic + Electrostatic Separation)

- Tantalum-niobium ore beneficiation solution (gravity + magnetic separation)

- Heavy Alluvial Ore Beneficiation Solutions (Gravity + Magnetic Separation)

- About Us

- Blog

- Contact Us

Menu

Comminution Equipment

Screening Equipment

Gravity Separation Equipment

Magnetic & Flotation Equipment

Gravity Separation for Hard Rock

- Rock Gold Ore Gravity Separation Solutions

- Primary Tin Ore Gravity Separation Solutions

- Chromite Ore Beneficiation Solution (Gravity + Magnetic Separation)

- Solution for ilmenite ore dressing (gravity + magnetic separation)

- Zirconium Ore Beneficiation Solution (Gravity + Magnetic + Electrostatic Separation)

- wolframite beneficiation solutions

- Barite Gravity Separation Solutions

- Antimony Ore Beneficiation Solutions (Gravity + Flotation)

- Waste incinerator bottom ash sorting solutions

Gravity Separation for Placer Deposits

- Alluvial Gold Ore Gravity Separation Solutions

- Tin Alluvial Ore Gravity Separation Solutions

- Coastal Placer Ore Beneficiation Solution

- Integrated Beneficiation Solution for Titanium-Zirconium Placer Ore (Gravity-Magnetic-Electrostatic)

- Chrome Alluvial Ore Beneficiation Solution (Gravity + Magnetic Separation)

- Offshore Tin Placer Ore Gravity Beneficiation Solution

- Gemstone Sand Ore Gravity Separation Solutions

- Zircon Sand Beneficiation Solution (Gravity + Magnetic + Electrostatic Separation)

- Tantalum-niobium ore beneficiation solution (gravity + magnetic separation)

- Heavy Alluvial Ore Beneficiation Solutions (Gravity + Magnetic Separation)