We provide free proposals and quotes 24/7.

Feel free to contact us via WeChat/WhatsApp: +8619914754015

Submit your inquiry, and we will provide you with a professional solution.

{{ variable.name }}

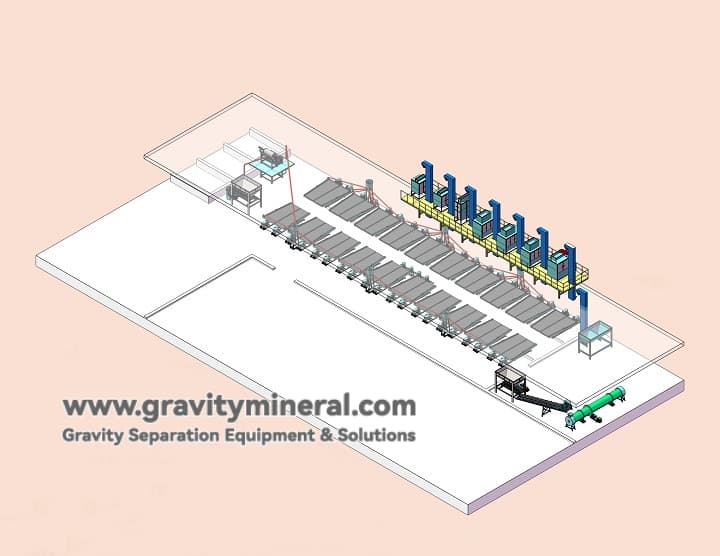

This zircon sand beneficiation solution provides a high-efficiency combined process centered on "wet gravity roughing + dry magnetic separation and electrostatic beneficiation" for zircon in seashore and river alluvial sands. Through multi-stage gravity enrichment, magnetic separation and electrostatic purification, it realizes efficient recovery and deep purification of zircon sand, and the content of ZrO₂ in the final product can be more than 65%.

Zircon sand is characterized by high density, weak magnetism and medium electrical conductivity, which is suitable for the combined process of "gravity pre-enrichment + magnetic separation / electrostatic purification". This zircon sand beneficiation solution realizes preliminary enrichment through wet gravity separation, and then deep purification through dry magnetic separation and high-pressure electrostatic separation, which has the characteristics of high recovery rate, excellent product quality, strong adaptability, etc. It can deal with the zircon sand with fine grain size of 0.1-0.5mm.

Wet roughing system

The raw ore is fed evenly through the silo and passed through the tumbler sieve (2-5mm hole) to classify and remove impurities;

The materials under the screen enter the spiral chute for roughing and sweeping (feeding concentration 30-40%), and initially enrich the zircon sand;

Gravity separation concentrate through the wet magnetic separator (field strength 1200-8000 gauss) to remove ilmenite, garnet and other magnetic minerals;

Finally, the shaking table is used to produce coarse zircon sand concentrate (ZrO₂ 50-55%).

Dry Concentration System

The coarse concentrate is dried by a dryer to create conditions for magnetic and electrostatic separation;

The dried material passes through the permanent magnetic drum magnetic separator to further remove the weak magnetic minerals;

Non-magnetic products enter the high-voltage electrostatic separator, utilizing the difference in electrical conductivity to separate zircon sand from rutile and other minerals;

Finally, the arc plate electrostatic separator or special magnetic separator for zircon ore is used for fine removal of impurities to obtain high purity zircon sand concentrate (ZrO₂≥65%).

Tailings and water recycling system

The utilization rate of process water recycling in the wet section is >90%, reducing water consumption;

Tailings are stockpiled or backfilled after dewatering treatment, in line with environmental protection requirements.

| Process Segment | Core equipment | Technical characteristics |

|---|---|---|

| Wet Screening | Tumbler screen | Multi-layer screen, wear-resistant and anti-clogging |

| Wet gravity | Glass fiber reinforced plastic spiral chute | Corrosion-resistant, high sorting efficiency |

| Wet magnetic separation | Permanent Magnet Cylinder Magnetic Separator | Strong magnetic mineral separation, field strength adjustable |

| Wet Separation | 6-S Shaking Table | Precision sorting to improve concentrate grade |

| Drying | Rotary dryer | High thermal efficiency and temperature control |

| Dry Magnetic Separation | Permanent Magnet Drum Magnetic Separator | Separation of weakly magnetic minerals |

| Electrostatic purification | High Voltage Electrostatic Separator | High-voltage electrostatic separation, precise separation of non-conductive impurities |

| Fine Selection | Arc plate electrostatic separator / zirconium ore special magnetic separator | Final removal of impurities to ensure high product purity |

Processing capacity: 10-600 t/d (can be customized)

Recovery rate: significantly higher than a single process

Concentrate grade: ZrO₂ ≥ 65

Water recycling utilization rate: >90

✅ High-efficiency sorting: gravity combined with magnetic and electrostatic sorting, high recovery rate, adapted to fine-grained zircon sand;

✅ Energy saving and environmental protection: water recycling in wet section, no chemicals added, green production;

✅ Economic investment: modularized design, adaptable to different scales, fast return on investment;

✅ Stable and reliable: the equipment is mature and durable, with easy maintenance and low operating costs.

We provide a full range of technical support for zircon sand beneficiation:

🔬 Design: process design and optimization, site planning, drawing design;

🛠️ Equipment and engineering: professional equipment selection and configuration, equipment supply, engineer door-to-door installation and commissioning guidance;

👨💻 Training and support: personnel operation training, production optimization and after-sales service;

🔧 Upgrade and guarantee: long-term technical consultation, spare parts supply and process upgrade.

If you have zircon sand beneficiation project requirements, welcome to contact us for customized solutions and quotations. We will provide you with professional, economical and reliable whole line zircon sand gravity-magnetic separation and electrostatic separation joint solution!

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.